Unlocking Warehouse Potential: How Flexible Conveyors Boost Efficiency Anywhere, Anytime

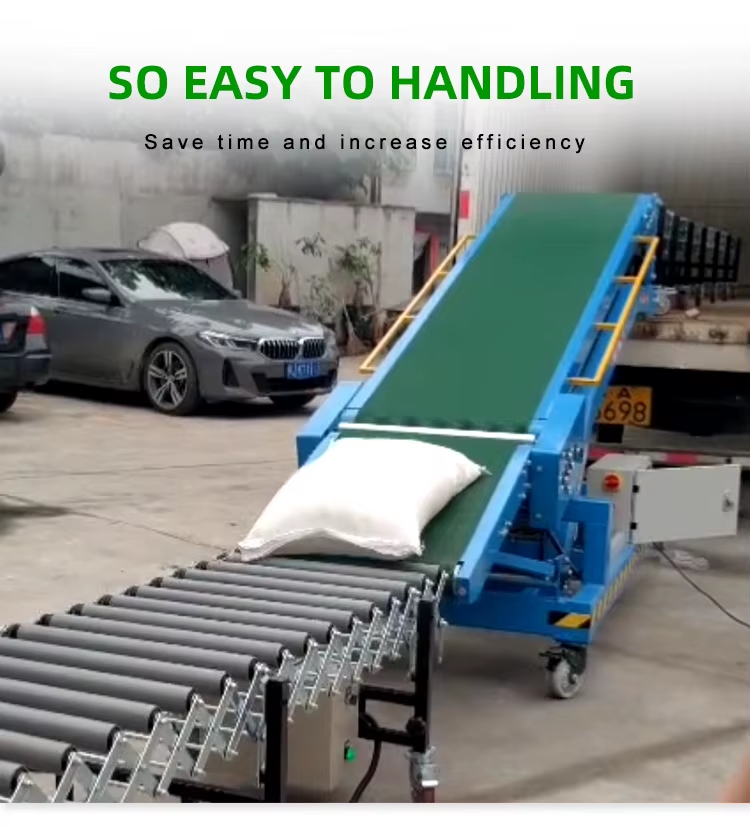

In today's fast-paced world of logistics and e-commerce, warehouses face more pressure than ever to move goods quickly, accurately, and affordably. While traditional fixed conveyor systems have long been a backbone of material handling, their rigid, permanent nature often becomes a bottleneck in dynamic evironments. Enter the game-changer: Flexible Conveyors.

Imagine a conveyor system that you can move as easily as a supermarket shopping cart, extend or shorten like a toy train set, and pack away when not in use. That’s the power of flexible conveyors. These innovative systems are transforming warehouses of all sizes by offering unparalleled adaptability, slashing operating costs, and turning any space—no matter how irregular or temporary—into a highly efficient workflow zone.

1. Easy and Flexible Movement: Your Workflow, Your Way

The standout feature of these systems is right in the name: flexibility. Forget the days of being locked into a single, permanent layout. Flexible conveyors are designed to be moved, adjusted, and reconfigured in minutes.

a) Roll Them Where You Need Them:

Most flexible conveyors are mounted on heavy-duty swivel casters with brakes. This means a single worker can easily steer and push a long section of conveyor, positioning it perfectly at a loading dock, snaking it through packing stations, or extending it into a truck bed. They are the ultimate "go-to" tool for managers who need to adapt their floor plan on the fly to meet the day's demands.

b) Assemble and Reconfigure in Minutes:

Think of them like LEGO bricks for your warehouse. Individual sections (typically 10 feet long) can be quickly connected together with simple pins or levers to form a continuous path of any length. Need to merge two lines into one? Use a Y-connector. Need to change the direction of flow? It’s as simple as unlinking a section, rolling it to a new position, and reconnecting. This modularity allows you to design custom workflows for different tasks:

Unloading Trucks: Create a straight shot from the back of a trailer directly to the receiving area.

Order Picking: Weave a conveyor through aisles so pickers can place items directly onto the belt, eliminating long walks back to a fixed station.

Sorting: Set up multiple lines to sort packages by destination, carrier, or priority.

c) Grow with Your Business:

You don’t need a massive upfront investment. Start with a few key units and add more sections as your business expands. This scalable approach makes automation accessible and protects your investment for the long term.

2. Lightning-Fast Loading and Unloading: No More Truck Jams

The loading dock is where time is money. Delays here cause backups, incur fees from trucking companies, and stress out your team. Flexible conveyors are the ultimate tool for clearing docks quickly.

a) Reach Right Into the Truck:

The most powerful trick? This is called "shotgunning." Instead of workers carrying boxes the full length of a 53-foot trailer, you simply roll a flexible conveyor right into the truck bed. Workers at the front of the trailer place boxes onto the belt, and the conveyor does the hard work of carrying them out to the dock. This turns a long, tiring walk into a simple pivot motion, dramatically speeding up the process.

b) Create a High-Speed Assembly Line:

A flexible conveyor turns a manual, chaotic unload into an organized, continuous flow. It acts like a moving highway for your goods. Workers can station themselves at optimal points—some inside the truck loading the belt, others at the dock scanning and palletizing the goods. This parallel processing cuts unload/load times by 50% or more.

c) A Safer, Less Painful Workday:

All that bending, twisting, and carrying heavy boxes down a long trailer is a leading cause of back injuries and fatigue. By bringing the conveyor to the work, employees can handle goods from a comfortable position, significantly reducing physical strain. A safer workplace means fewer injuries, lower workers' compensation costs, and happier, more productive employees.

3. Huge Savings on Time and Labor: Doing More with Less

Labor is the single biggest cost in most warehouses. Finding ways to improve efficiency without adding headcount is the key to profitability. Flexible conveyors are a powerful solution.

a) Cut Man-Hours Drastically:

A task that usually takes four people two hours can often be done by two people in thirty minutes with a flexible conveyor. The system automates the most time-consuming part: transportation. This frees up your team to focus on more skilled tasks that can't be automated, like quality control or complex problem-solving. The savings on labor costs can often pay for the conveyor system itself in a matter of months.

b) The End of "Double-Handling":

In a manual process, a box might be touched multiple times: picked up in the truck, set down on a pallet, picked up again to be scanned, and set down again. Every time a product is handled, it costs you time and money. Flexible conveyors create a "one-touch" flow. An item is placed on the belt and isn't touched again until it reaches its final destination for palletizing. This streamlined process eliminates wasted effort.

c) Avoid Costly Truck Delays:

Trucking companies charge hefty fees (called detention) if their drivers and trailers are held up at your dock for too long. By slashing load/unload times, you get trucks in and out faster. This avoids these fees, allows you to process more trucks per day with the same number of docks, and makes you a preferred partner for carriers.

4. Works Anywhere, Anytire: Break Free from Space Limits

Not every warehouse is a perfect, new building. Flexible conveyors thrive in challenging, changing, or temporary environments where fixed systems would fail.

a) The Perfect Fit for 3PLs and Multi-Use Facilities:

Third-Party Logistics (3PL) providers work with many different clients, each with unique products and workflows. A fixed conveyor built for one client is useless for the next. Flexible conveyors allow them to create a custom flow for each client's goods every single day, making them incredibly agile and competitive.

b) Conquer Awkward Spaces:

Got pillars, tight corners, narrow doorways, or low ceilings? Fixed conveyors are often impossible or wildly expensive to install in older or irregular buildings. Flexible conveyors can be easily navigated around any obstacle, making efficient automation possible in virtually any facility.

c) Perfect for Seasonal Peaks and Pop-Up Operations:

Why invest in a permanent system you only need for the holiday rush? Flexible conveyors are the ideal "surge" solution. You can rent them or use your own for a few busy months to handle the extra volume, and then simply roll them into storage when things calm down. This makes seasonal scaling affordable and efficient.

d) Store Them Away:

When the job is done, they don’t clutter your floor. Disconnect the sections, and they can be rolled to a corner and stored vertically on a rack, freeing up every square foot of precious space for other activities.

Conclusion: The Smart Choice for a Agile Future

Implementing flexible conveyors isn't just about buying new equipment; it's about investing in a new way of thinking. It’s choosing adaptability over rigidity, efficiency over wasted effort, and smart automation over back-breaking manual labor.

The benefits are clear:

Move them like a cart to create the perfect layout for any task.

Turn truck unloading from a chore into a rapid-fire process.

Save real money on labor costs and avoid expensive delays.

Turn any space—big, small, old, or temporary—into a productive hub.

In a world where customer demand can change overnight, the ability to adapt your operation quickly is the ultimate superpower. Flexible conveyors give you that power, offering a simple, affordable, and incredibly effective way to build a smarter, faster, and more resilient warehouse.