The relentless hum of material handling is the heartbeat of global commerce. From sprawling automotive assembly plants to the

lightning-fast sortation hubs of e-commerce giants and the meticulous production lines of pharmaceuticals, the efficient movement

of goods is paramount. At the core of this intricate dance lie two fundamental workhorses: the chain conveyor and the roller conveyor.

While seemingly simple, the choice between these systems represents a critical strategic decision impacting efficiency, cost, flexibility,

and ultimately, the bottom line. As automation surges and supply chains demand unprecedented agility, understanding the nuanced

strengths, limitations, and evolving applications of these technologies is more vital than ever.

The Indispensable Conveyor: Backbone of Industry

Before diving into the comparison, consider the scale. The global conveyor system market, valued at over $8.5 billion in 2023, is projected

to exceed $12 billion by 2030, driven by e-commerce growth, manufacturing automation, and warehouse modernization (Global Logistics

Tech Report, 2024). Within this vast ecosystem, chain and roller conveyors constitute a dominant share. Their selection isn't merely an

engineering choice; it's a commitment to an operational philosophy.

Chain Conveyors: The Powerhouse of Heavy Hauling

Imagine a robust, interlinked metal chain moving relentlessly along a track. This is the essence of the chain conveyor. Driven by powerful

motors via sprockets, chains excel where brute force and unwavering reliability are non-negotiable.

Advantages of Chain Conveyors

Diving into the advantages of chain conveyors will shine a light on why they're a popular choice for many industrial applications. Here’s a breakdown that’s both insightful and straightforward.

Robust Durability for Heavy Loads

One of the standout advantages of chain conveyors is their unmatched durability. Designed to withstand heavy-duty use, these conveyors can easily handle large, heavy loads without batting an eye.

Whether you’re moving automotive parts, heavy machinery, or bulk materials, chain conveyors are up to the task. Their strength lies in the robust design, which ensures longevity and reliability in even the toughest industrial environments.

Versatility Across Applications

Chain conveyors are incredibly versatile. They're not just limited to moving boxes on a straight line; they can transport a variety of materials including pallets, assembly lines, and even scrap metal.

Their design allows for customization to fit specific needs—be it incorporating different chain materials, and attachments, or adapting to various layouts. This versatility makes them a go-to solution for industries ranging from automotive to food processing, where diverse conveying needs are a given.

Enhanced Productivity with Minimal Downtime

Efficiency is key in any operation, and chain conveyors deliver by enhancing productivity. They're designed for continuous, reliable operation, minimizing downtime. With chain conveyors, materials move swiftly and smoothly along the production line, keeping operations flowing and reducing bottlenecks. This continuous movement is crucial for meeting production deadlines and maintaining a high output level.

Adaptable to Harsh Environments

Chain conveyors thrive in environments where other systems might falter. They're built tough, and capable of operating in conditions that are dusty, hot, or corrosive. This resilience makes them an ideal choice for industries like mining, construction, and metalworking, where challenging conditions are part of the daily grind. Their ability to keep moving materials, undeterred by the surroundings, is a significant advantage.

Safe and Reliable Material Handling

Safety in material handling is paramount, and chain conveyors contribute positively in this area. They offer a secure way to transport materials, reducing the risk of spillage or damage. Their sturdy construction and reliable operation mean fewer accidents and less material loss. Moreover, with the right safety features and regular maintenance, chain conveyors are a safe choice for workers and materials alike.

Long-term Cost Savings

While the initial investment in a slat chain conveyor might be higher than other types, the long-term savings are undeniable. Their durability and low maintenance requirements mean reduced repair costs and less frequent replacements. Over time, these savings add up, making chain conveyors a cost-effective choice for businesses looking for a reliable, long-term material handling solution.

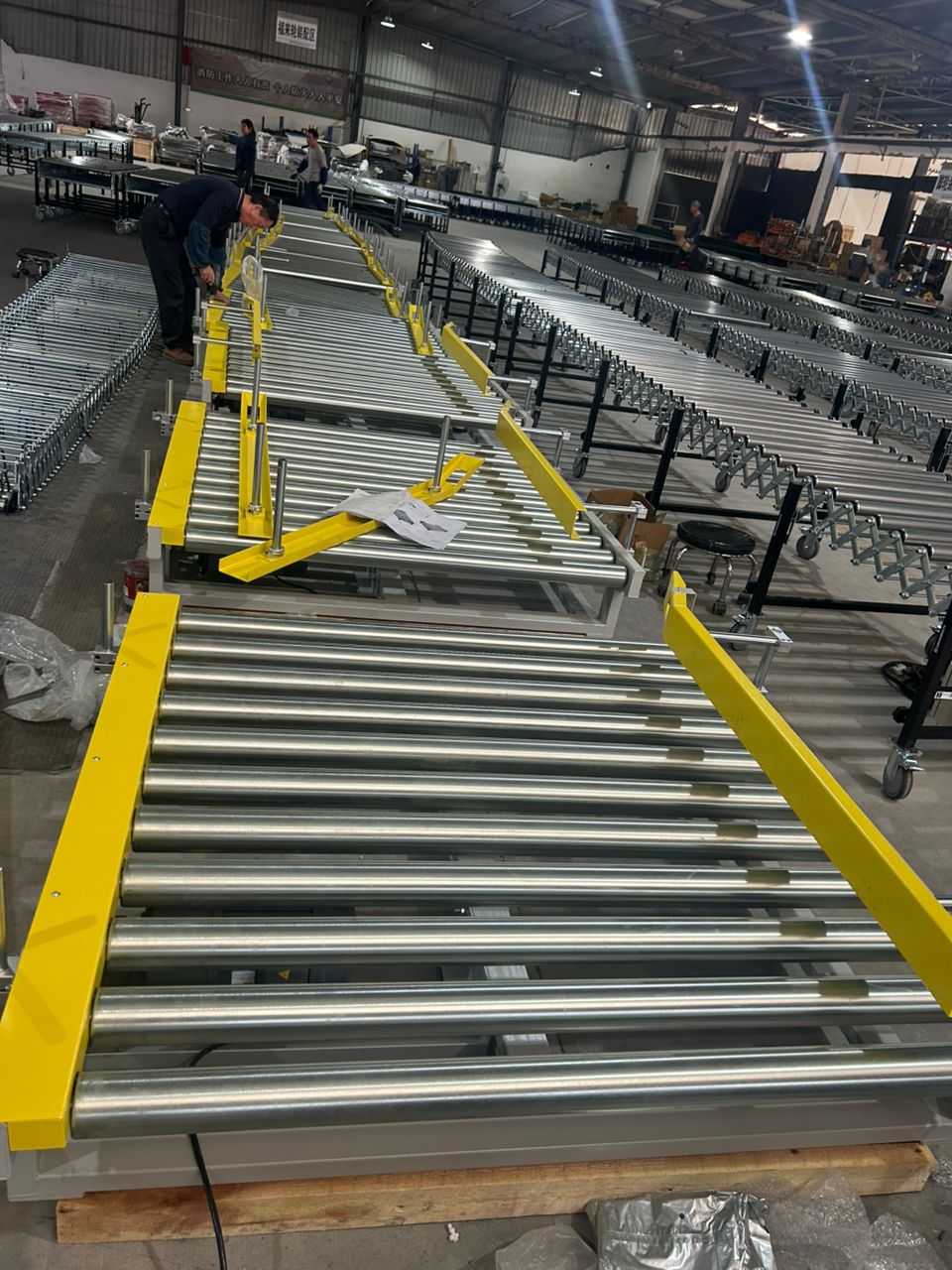

Roller Conveyors: The Agility Experts

On the flip side, roller conveyors are the go-to for light to medium loads. They consist of rollers mounted in a frame, over which goods can glide with ease. This simplicity in design translates to efficiency and cost-effectiveness, especially for operations that require straightforward material movement.

Advantages of Roller Conveyors

Roller conveyors are a staple in the material handling industry, celebrated for their simplicity and efficiency. Let's break down their advantages to understand why they're often the conveyor of choice for a variety of operations.

Simplicity and Ease of Maintenance

First up, roller conveyors win big on simplicity. Their straightforward design—comprising rollers mounted in a frame—makes them not only easy to use but also incredibly easy to maintain.

This simplicity translates to lower downtime and reduced maintenance costs. When a part does need replacing, it’s usually a quick and hassle-free process, minimizing disruption to your operations.

Cost-Effectiveness

When it comes to cost, roller conveyors are hard to beat. They're generally less expensive to install than many other conveyor types, making them an attractive option for businesses looking to optimize their operations without breaking the bank.

Additionally, their energy efficiency, especially in the case of gravity roller conveyors, can lead to significant savings on electricity bills, adding to their cost-effectiveness over time.

Versatility in Handling Various Materials

Don’t let their simplicity fool you; roller conveyors are surprisingly versatile. They can handle a wide range of items, from boxes and pallets to crates and trays, making them suitable for various industries, including manufacturing, distribution, and retail.

Moreover, they can be customized with different roller sizes, materials, and spacings to accommodate specific types of goods, enhancing their versatility.

Energy Efficiency

Many roller conveyors operate on gravity, meaning they don’t require power for movement, which is a boon for energy efficiency. Even powered roller conveyors are designed to consume less energy, thanks to their efficient design that moves goods with minimal friction. This energy-saving feature not only reduces operational costs but also supports eco-friendly business practices.

Safety and Productivity

Roller conveyors contribute positively to workplace safety and productivity. They provide a stable platform for goods, reducing the risk of damage during transport and minimizing the need for manual handling, which can lead to workplace injuries.

By streamlining the movement of materials, they also enhance productivity, ensuring goods are moved quickly and efficiently through the production line or warehouse.

Scalability and Flexibility

Another significant advantage of roller conveyors is their scalability and flexibility. They can be easily extended, reconfigured, or integrated with other conveyor systems as your business grows or as operational needs change.

This adaptability makes roller conveyors a long-term investment, capable of evolving alongside your business.

Comparing Chain And Roller Conveyors

When it comes down to choosing between chain and roller conveyors, the decision hinges on the specific needs of your operation. Chain conveyors excel in heavy-duty applications and environments that demand durability, while roller conveyors are the go-to for lighter loads and high efficiency, offering versatility and cost savings in less demanding conditions.

Application and Suitability

Choosing between a chain and roller conveyor comes down to understanding your material handling needs. Chain conveyors are your heavy lifters, ideal for rugged environments and heavy loads. Roller conveyors, however, excel in lighter applications, where simplicity and cost-effectiveness are priorities.

Cost Implications

The initial investment in a chain conveyor is higher, but for applications requiring its robust design, this cost is justified. Roller conveyors, being less expensive, can offer quick returns on investment in the right scenarios. Maintenance costs also play a crucial role, with chain conveyors requiring more upkeep.

Performance and Efficiency

In terms of performance, chain conveyors offer versatility and strength, capable of handling a wider variety of tasks. Roller conveyors, while limited in scope, provide efficient, low-cost operation for their intended applications. Energy consumption and noise levels are also critical factors, with roller conveyors generally offering a quieter, more energy-efficient solution.

Conclusion: Choosing the Right Tool for the Industrial Symphony

Selecting between chain and roller technology is a decision echoing through years of operation, impacting efficiency, cost,

safety, and adaptability. Chain conveyors remain the undisputed titans of raw power, conquering extreme loads, punishing

environments, and demanding inclines with rugged reliability. Roller conveyors, particularly the agile and efficient Motorized

Roller (MDR) variants, are the champions of flexibility, gentle handling, energy conservation, and modern warehouse dynamism

By understanding the strengths and limitations of each system, you can select the option that best meets your needs, ensuring smooth operations and optimal productivity. Remember, the right conveyor system is out there for every task; it's just a matter of matching it to your specific requirements.