Introduction

In today’s fast-paced industrial landscape, efficiency and adaptability are key to maintaining competitive advantage. One of the most significant innovations in material handling and production lines is the modular conveyor system. These systems have revolutionized manufacturing, warehousing, and logistics by offering flexible, scalable, and cost-effective solutions for transporting goods.

This article explores the concept of modular conveyor systems, their components, benefits, applications, and future trends. By the end, readers will have a comprehensive understanding of why these systems are becoming indispensable in modern industries.

1. Understanding Modular Conveyor Systems

1.1 Definition

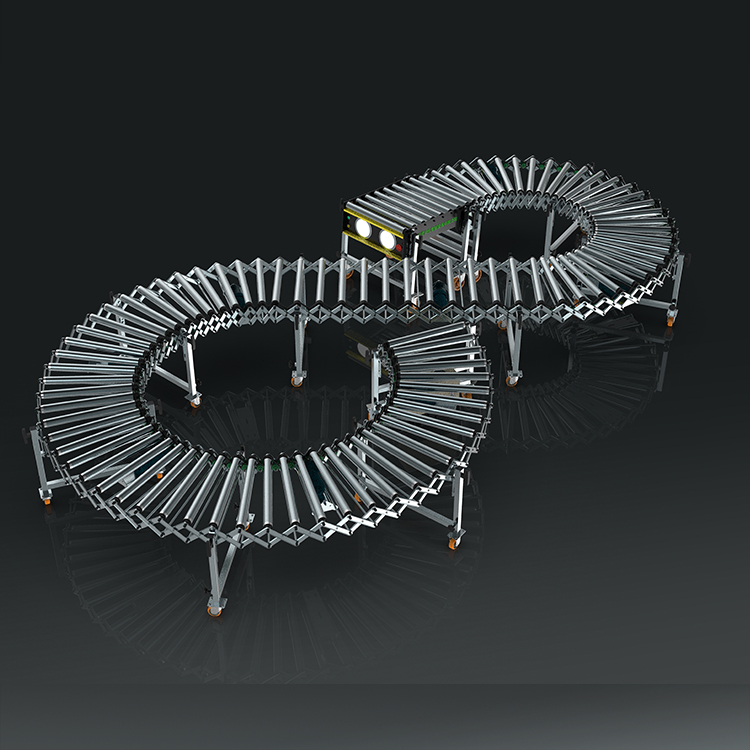

A modular conveyor system is a customizable, reconfigurable conveyor setup made up of standardized, interchangeable components. Unlike traditional fixed conveyors, modular systems allow for easy expansion, modification, and relocation to meet changing production needs.

1.2 How It Works

Modular conveyors consist of individual segments (modules) that can be connected in various configurations—straight, curved, inclined, or declined—to fit different facility layouts. These systems can be powered by electric motors, gravity, or manual operation, depending on the application.

1.3 Key Features

Modularity: Components can be added, removed, or rearranged.

Scalability: Systems can expand as business needs grow.

Versatility: Suitable for diverse industries, from food processing to automotive manufacturing.

Durability: Made from high-quality materials like stainless steel, plastic, or aluminum.

Ease of Maintenance: Individual modules can be replaced without shutting down the entire system.

2. Components of a Modular Conveyor System

A modular conveyor system is composed of several key parts:

2.1 Conveyor Belts

Plastic Modular Belts: Made of interlocking plastic segments, ideal for food and beverage industries.

Fabric Belts: Used for lightweight products.

Metal Belts: Suitable for high-temperature or heavy-duty applications.

2.2 Frames & Supports

Adjustable legs and frames provide stability and height customization.

2.3 Drive Units

Electric motors or gearboxes power the conveyor movement.

2.4 Rollers & Wheels

Used in roller conveyors for smooth product movement.

2.5 Control Systems

PLCs (Programmable Logic Controllers) and sensors automate operations.

3. Types of Modular Conveyor Systems

Different industries require different conveyor configurations. The most common types include:

3.1 Belt Conveyors

Flat or textured belts for transporting items of various shapes and sizes.

3.2 Roller Conveyors

Gravity or powered rollers for moving heavy loads like pallets.

3.3 Chain Conveyors

Ideal for heavy-duty applications, such as automotive assembly lines.

3.4 Spiral Conveyors

Used for vertical transportation in limited spaces.

3.5 Overhead Conveyors

Suspended systems for maximizing floor space in warehouses.

4. Benefits of Modular Conveyor Systems

4.1 Flexibility & Customization

Easily reconfigured to adapt to new production layouts.

4.2 Cost-Effectiveness

Reduced installation and maintenance costs compared to fixed systems.

4.3 Improved Efficiency

Minimizes manual handling, speeding up operations.

4.4 Space Optimization

Can be designed to fit tight or unconventional spaces.

4.5 Enhanced Safety

Reduced risk of workplace injuries with automated material handling.

4.6 Sustainability

Energy-efficient designs and recyclable materials contribute to greener operations.

5. Applications Across Industries

Modular conveyor systems are used in various sectors:

5.1 Manufacturing

Automotive, electronics, and consumer goods assembly lines.

5.2 Food & Beverage

Hygienic designs for processing, packaging, and sorting.

5.3 Pharmaceuticals

Clean, contamination-free transport of medical products.

5.4 Logistics & Warehousing

Automated sorting and distribution in e-commerce fulfillment centers.

5.5 Mining & Construction

Heavy-duty conveyors for transporting raw materials.

6. Future Trends in Modular Conveyor Systems

6.1 Smart Conveyors with IoT Integration

Real-time monitoring and predictive maintenance using IoT sensors.

6.2 AI & Automation

AI-driven sorting and robotic integration for fully automated logistics.

6.3 Energy-Efficient Designs

Solar-powered and low-energy consumption conveyors.

6.4 3D Printing for Custom Components

On-demand production of specialized conveyor parts.

7. Conclusion

Modular conveyor systems represent the future of industrial material handling. Their flexibility, efficiency, and adaptability make them essential for businesses looking to optimize operations. As technology advances, these systems will continue to evolve, integrating AI, IoT, and sustainable practices to meet the demands of Industry 4.0.

Investing in a modular conveyor system is not just an upgrade—it’s a strategic move toward long-term productivity and competitiveness.